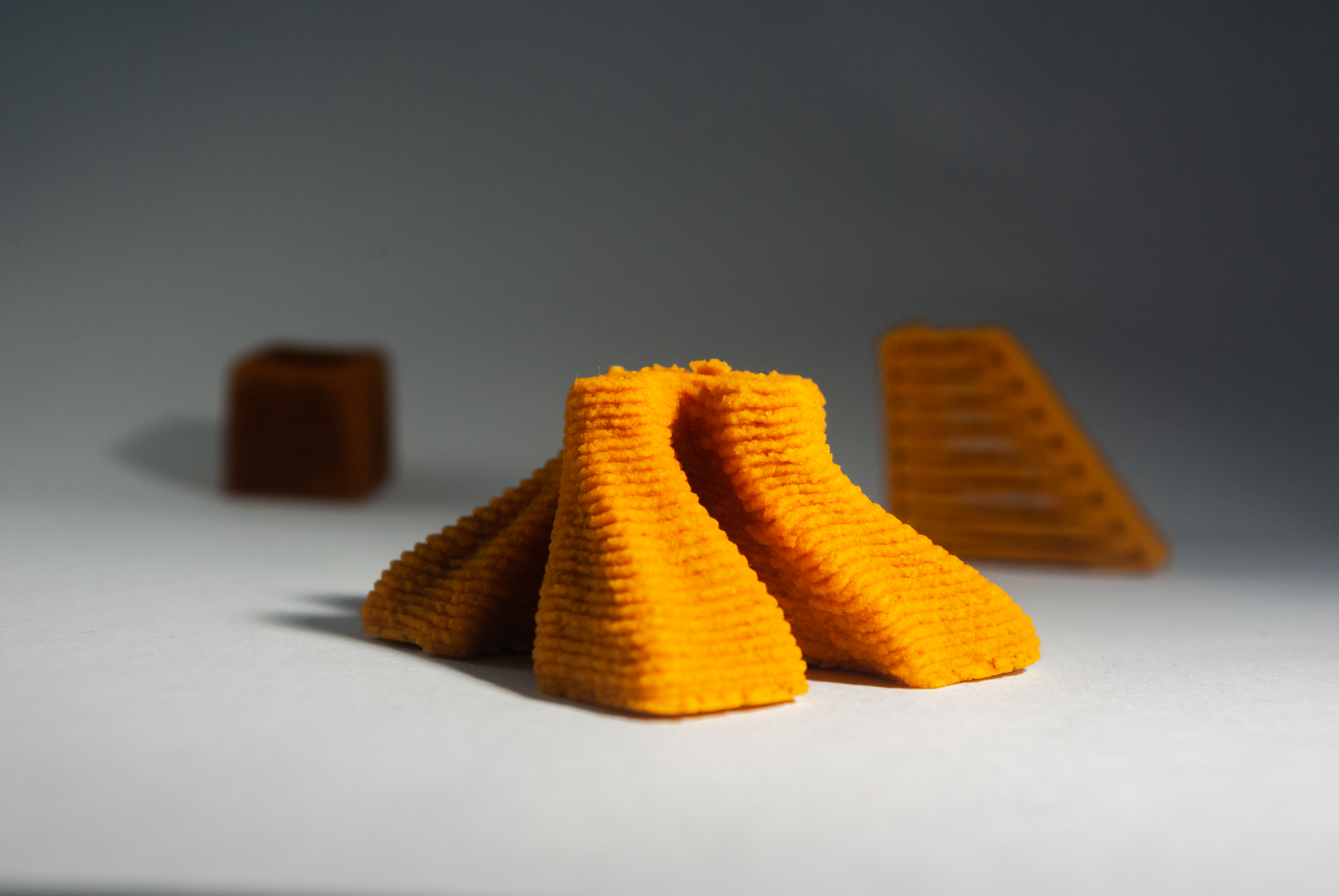

Energy use in contemporary 3d printing processes are almost entirely defined by heating up (bio)plastic filaments for printing. This energy can be conserved if a material could be developed which does not need to be heated. The paste developed in this project consists of organic powders mixed with fluids that evaporate leaving behind a solid powder based shape.

Paste printing is currently in its early days, but will eventually shape a sustainable future. A material which is now considered waste gains new value as a sustainable alternative for 3d printing.

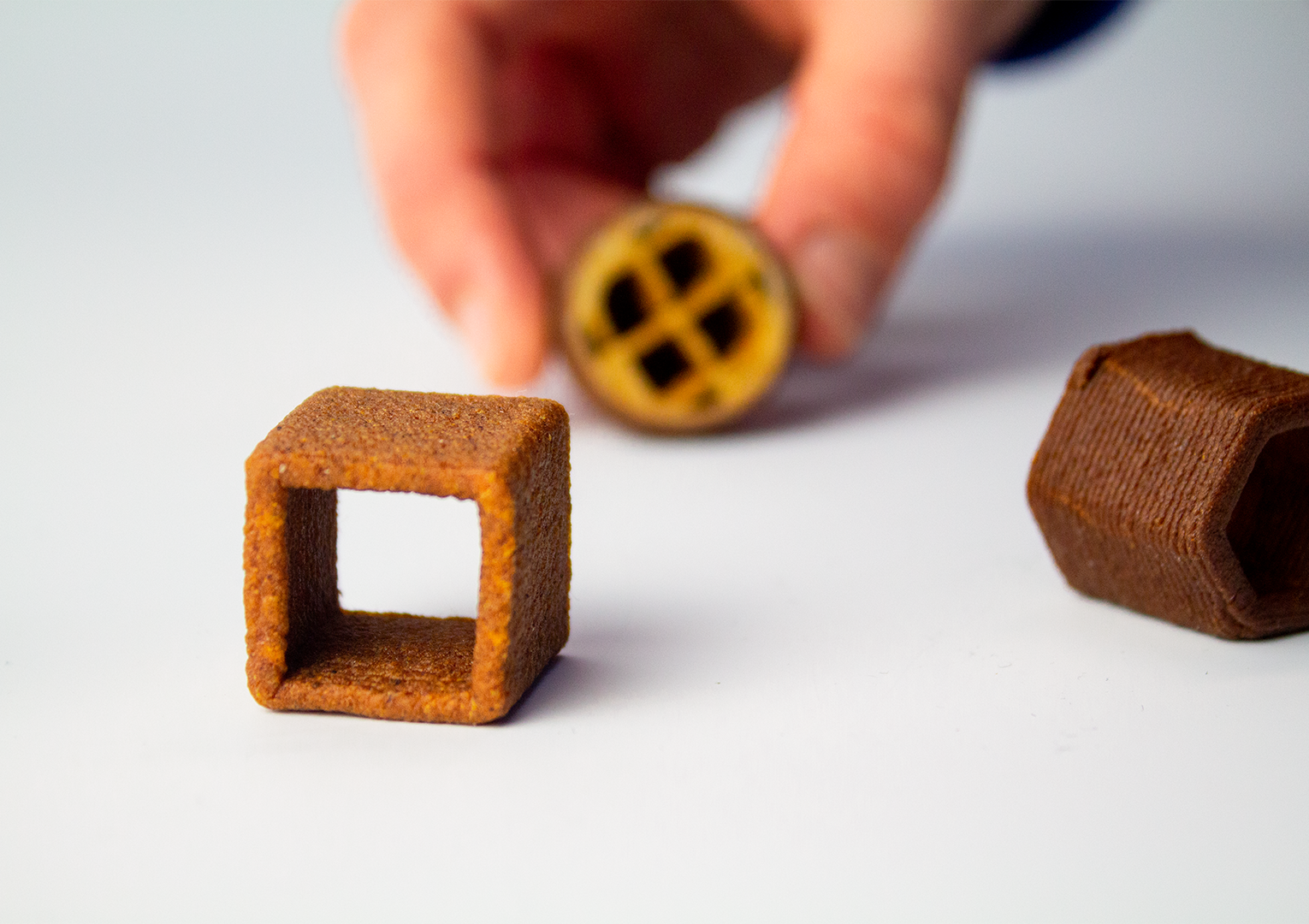

A paste is made from mandarine powder. This is pushed through a syringe which replaces the traditional extruder. With this mechanism an object can be 3d printed. The print needs 24 hours to dry, which is made easier by replacing the print beds – the surface on which the 3d print is printed. In this way the printing process can continue while earlier 3d prints are drying.

Don't waste, use paste! A technological future with 3D organic recyclable paste printing

About Minor Advanced Prototyping

The Interactive Environments minor is a 3rd year course of the bachelor program in which interaction design on an architectural scale is taught in 5 months. Students work with iterative design processes in which making is paramount. As a result, they learn what interactive technology can do and what skills you need to shape interactions with this technology. This field is multidisciplinary, which students in the minor experience by working together with fellow students from different disciplines.

TU Delft Minor Advanced Prototyping teachers: Willemijn Elkhuizen, Freerk Wilbers, Noor Doucet, Eliza Noordhoek and Erik Thomassen.

IO TU DelftThanks to

Made by Minor Advanced Prototyping students:

Tinka de Leeuw, Nandus Lemlijn, Joas van Brummelen, Eimhear Morris

Supervised by: Jeremy Faludi